How to choose mud pump or air compressor system for UY crawler water well drilling rig?

In water well drilling operation, both mud pump system and air compressor system play a key role, which directly affects drilling efficiency, quality and adaptability to different geological conditions. The actual purchase, customers often put forward a variety of questions, the following is a detailed answer for you.

I.When does UY crawler water well drilling rig need to be equipped with mud pump?

Mud pump is usually a reciprocating pump. Its work, through the crank connecting rod mechanism will power the rotary motion of the engine is converted to the reciprocating motion of the piston in the pump cylinder. When the piston backward movement, the pump chamber volume increases, the pressure decreases, the mud in the atmospheric pressure, through the suction pipe into the pump chamber, complete the suction process; when the piston forward movement, the pump chamber volume decreases, the pressure rises, the mud is extruded, through the discharge pipe, to realize the process of liquid discharge. The mud is squeezed and discharged through the discharge pipe to realize the process of liquid discharge. The mud is continuously transported to the borehole in such a cycle to meet the needs of wall protection, cooling of drill bit and slag discharge.

(1) What are the applicable geological conditions for UY crawler water well drilling rig equipped with mud pump?

1.Soft rock layers with low compressive strength: soft rock layers such as mudstone and weathered sandstone with compressive strength less than 50MPa have loose rock structure, and the wall of the hole is easy to collapse when drilling. For example, this kind of soft rock is more common in the shallow geological structure in some mountainous areas.

2.Loose and easy to collapse strata: gravel layer, quicksand layer, silt layer, etc., the bond between particles is weak, such as the strata near the river bank, this situation often occurs, and special attention should be paid to preventing collapse when drilling.

(2) What are the advantages of UY crawler water well drilling rig equipped with mud pump?

1.wall protection and anti-collapse: mud can form a dense mud skin with specific gravity of 1.05 – 1.25g/cm³ on the hole wall, which is like putting a strong protective suit on the hole wall, resisting the formation pressure and preventing collapse.

2.Cooling and lubrication: When the drill bit is drilling and rubbing with the rock, the mud can absorb the heat, reduce the temperature of the drill bit, reduce the wear and tear, so that the life of the drill bit can be increased by 30% – 50%, and save the cost.

3.Slag removal and rock carrying: control the mud upward flow rate in the annulus ≥ 0.3m/s, it can bring the rock chips out of the ground, prevent clogging of the borehole, and ensure the smooth drilling of the borehole.

(3)What is the common combination of water well drilling rig with mud pump?

Usually it is water well drilling rig + mud pump + drill pipe + three-tooth wheel bit. This kind of collocation in the soft rock and loose stratum of the water well drilling effect is remarkable.

II.When is the UY crawler water well drilling rig equipped with an air compressor?

Air compressors are generally categorized into volumetric type and power type. Volumetric air compressor increases air pressure by reducing the volume of air, take piston air compressor as an example, the motor drives the crankshaft to rotate, and the connecting rod makes the piston to do reciprocating motion, when the piston moves backward, the cylinder volume increases, the pressure decreases, and the air is sucked into the cylinder; when the piston moves forward, the cylinder volume decreases, the air is compressed, and the pressure rises, and then it is discharged. Power air compressor relies on the high-speed rotating impeller to do work on the air, so that the air to obtain kinetic energy, and then in the diffuser, kinetic energy is converted into pressure energy, so as to output high-pressure air. No matter which type, the ultimate purpose of the air compressor is to provide high-pressure gas for the submerged hammer and other equipment to realize the impact crushing and slag discharge function.

(1) What are the applicable geological conditions for UY crawler water well drilling rigs equipped with air compressors?

1.medium-hard to hard rock formations: rocks with compressive strength of 50 – 250MPa, high hardness, such as granite, etc., which need air compressor and submerged hammer to generate high-frequency impact to break.

2.Fissure development stratum: air can flow in the fissure and blow out the debris, for example, some rock layers in mountainous areas are suitable for this method as more fissures are produced by geological movement.

(2) What are the advantages of UY crawler water well drilling rig with air compressor?

1.Impact crushing: air compressor provides high-pressure air to drive the submerged hammer, impact crushing on hard rock, high drilling efficiency, and obvious advantages in drilling in hard rock areas.

2.Dry slag removal: compressed air directly blows the rock chips out of the surface, without the need to deal with mud like mud slag removal, a simple process.

3.Water conservation and environmental protection: air drilling does not need to prepare mud, saving 60% of water than mud drilling, which is very suitable in water-scarce areas or places with high environmental protection requirements.

(3)What is the common combination of UY crawler water well drilling rig with air compressor?

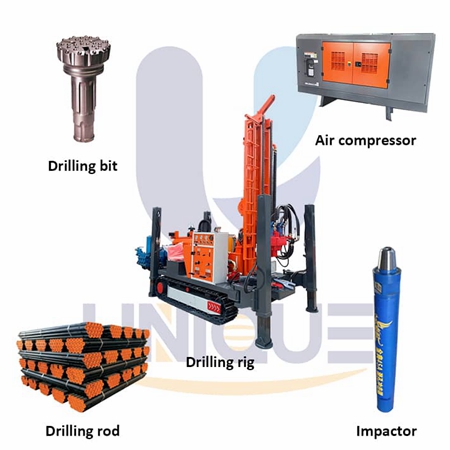

Generally it is water well drilling rig + drill pipe + air compressor + drill bit + impactor, which can give full play to the advantages of air compressor in drilling hard rock and fissure stratum.

III. Can customer choose both mud pump system and air compressor system for water well drilling rig?

(1) Under what circumstances can a UY crawler water well drilling rig be equipped with both a mud pump system and an air compressor system?

1.Complex alternating formations: For example, in “soft on top and hard on the bottom” formations, the upper loose layer is protected by mud pump, and the lower hard rock is broken by air compressor, like some alternating sedimentary rock and granite formations.

2.High-precision projects: hydrological monitoring wells, ground-source heat pump wells, etc., which have high requirements for drilling process and need to switch the process quickly, both systems are equipped at the same time to meet the demand.

3.Emergency standby: when one set of system fails, the other set can continue to work, to ensure that the project does not stop, to avoid delays in the schedule.

(2) How to realize the two technically?

1.Quick switching module – water/air duplex valve manifold: switching mud/air lines within 10 seconds, realizing quick mode changeover.

2.Drill pipe adapter: Compatible with double-wall (mud) and single-wall (air) drill pipes, improving equipment versatility.

3.Automatic identification function: The system automatically identifies sudden changes in resistance during drilling and prompts switching to impact mode, realizing intelligent operation.

(3) What is the common combination?

Water well drilling rig + drill pipe + air compressor + drill bit + impactor + mud pump + three-tooth wheel bit. This combination can cope with complex geology and high precision requirements.

IV.If UY crawler water well drilling rig is equipped with both mud pump and air compressor system, how should the water well drilling rig operate?

(1)When encountering complex alternating formations such as “soft on the top and hard on the bottom”, start the mud pump system when drilling into the upper loose layer. Adjust the parameters of the mud pump so that the specific gravity and flow rate of the mud meet the requirements of wall protection, collapse prevention and slag discharge, and then drill slowly, paying attention to the stability of the hole wall at all times. When drilling to the lower hard rock layer, switch to the air compressor system within 10 seconds through the water and gas duplex valves, and at the same time, change to the appropriate single-wall drilling rods and impactors and other equipment. Adjust the output pressure of the air compressor according to the hardness of the rock, drive the submerged hammer to impact and break the rock, and maintain a suitable drilling speed to prevent jamming.

(2)In high-precision projects such as hydrological monitoring wells and ground source heat pump wells, the mud pump and air compressor systems are switched at any time with the fast switching module according to the requirements of the project for the drilling process. During the drilling process, with the help of automatic identification function, when the system detects the sudden change of resistance, it switches the working mode in time. For example, when encountering local hard rock section, the drilling mode is quickly switched from mud drilling mode to air percussion drilling mode; through the drill pipe adapter, it ensures that the drill pipe is adapted to different systems to ensure drilling accuracy and efficiency.

(3)If one of the mud pump or air compressor systems fails, immediately start the backup system. If the mud pump fails, quickly switch to the air compressor system, and at the same time check the cause of the mud pump failure and carry out repairs; if the air compressor fails, promptly activate the mud pump system to continue drilling. In this process, according to the characteristics of the backup system, adjust the drilling parameters appropriately, such as mud pump system to control the mud performance, air compressor system to adjust the air pressure, etc., to ensure that the project is carried out continuously, to avoid schedule delays. In conclusion, to choose mud pump or air compressor system of water well drilling rig, we should comprehensively consider the geological conditions, project requirements and functional advantages of the equipment to make the most suitable choice and improve the efficiency and quality of water well drilling.

In conclusion, to select mud pump or air compressor system for UY crawler water well drilling rig, we should comprehensively consider the geological conditions, project requirements and functional advantages of the equipment to make the most suitable choice to enhance the efficiency and quality of water well drilling.

If you don’t know how to choose to equip mud pump system or air compressor system, please tell us the drilling depth, drilling hole diameter and geological condition you need, our sales manager will make suitable suggestions for you according to his rich experience.