YX-452T/452H Integrated Drill Rig

Integrated open-air down-the-hole drill carriage is advanced drilling equipment that integrates the down-the-hole drilling system and the screw air compression system. It is equipped with Yuchai’s six-cylinder country four-engine, compact structure, good integrity, and easy to move.

Product Description

Integrated open-air down-the-hole drill carriage is advanced drilling equipment that integrates the down-the-hole drilling system and the screw air compression system. It is equipped with Yuchai’s six-cylinder country four-engine, compact structure, good integrity, and easy to move. The drilling rig has the characteristics of energy-saving, high efficiency, safety, and environmental protection, flexible maneuverability, convenient operation, and stable performance. The specific performance is as follows:

1. The structure of the drill rig is compact, which is an organic combination of the open-air DTH drill rig and the air pressure screw machine.

2. The drilling rig is equipped with a single-stage mid-air pressure screw main engine, with a flow rate ( 10m 3 /min ), air pressure ( 1.5MPa ), and a mid-air pressure pneumatic impact, which has high efficiency and low energy consumption.

3. The rig has a low center of gravity and balanced distribution. It is equipped with a heavy-duty " four wheels and one belt " and has a 19° automatic leveling device and a double locking system that can be independently controlled, which improves the stability of the whole machine and adapts to different conditions. The drilling rig is equipped with a two-speed walking motor + reducer structure, achieving a perfect combination of speed and power.

4. The large displacement hydraulic pump is directly installed on the rear power port of the engine, and the structure is simple and reduces the source of failure.

5. The large-scale luffing boom system can meet the needs of different stations under various working conditions, especially for drilling low-level horizontal holes.

6. With a highly integrated hydraulic control system and a centralized operating platform, one station can freely control the entire machine.

7. The drilling rig is equipped with a rotary advancing speed switching valve, which can be adjusted in time according to the different characteristics and different working conditions of the rock to be drilled. The drilling speed is fast and the hole formation rate is high.

8. The machine is equipped with a real-time monitoring system and a stable self-protection system, which can accurately reflect and control the working status of the drilling rig. It can automatically shut down if it exceeds the set range or fails.

The efficient two-stage dry powder dust collection system greatly improves the working environment and conforms to the concept of energy-saving and environmental protection.

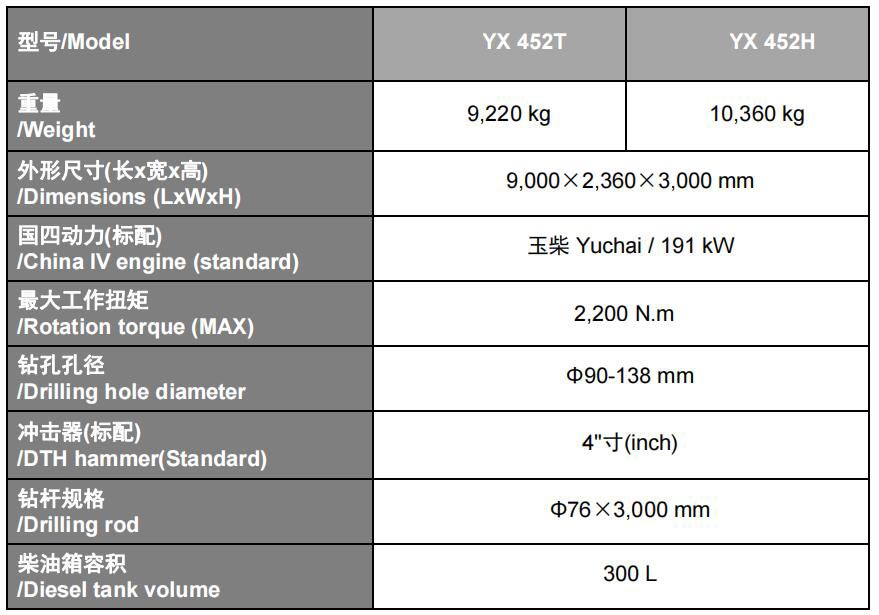

Technical Parameters